Describe How to Cut External Threads Using Hand Dies

Now check the thread pitch using screw pitch gauge. You need the threading tools for external threads are file round rod vise for clamping round die die stock flat-tip screwdriver and cutting spray.

Successful External Threads With A Die Mechanical Elements

Therefore in manual thread cutting normal wrench usage is to cut the threads 12 to 23 of a turn 180 to 240 degree rotation then reverse the tap for about 16 of a turn 60 degrees until the chips are.

. Another of the new Basic Skills family of short videos this one covers how to use a die to cut an external thread on a length of rodAlthough this is mo. Describe the procedure for cutting external threads by hand with a single-piece die. Drill a small pilot hole in the center of the broken screw or bolt.

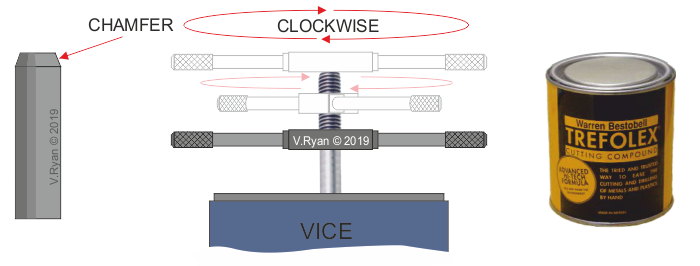

File the edges of the round rod and chamfer it at 45 which should be slightly larger than the thread depth. A hand tap cannot cut its threads in a single rotation because it creates long chips which quickly jam the tap an effect known as crowding citation needed possibly breaking it. If its correct then proceed to next step.

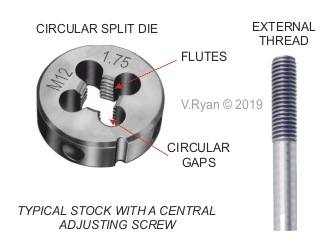

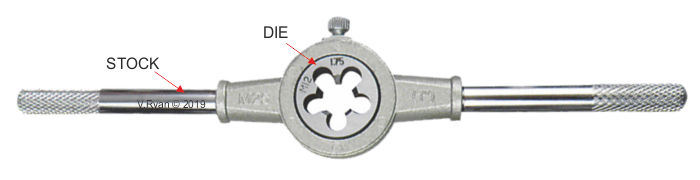

How To Cut Threads Using Taps and Dies. The workpiece is clamped in the lathe chuck and the threading die is held and rotated using a die handle. In general round-shaped dies are for cutting threads onto a workpiece and hex-shaped dies are for chasing cleaning up repairing existing threads.

If possible use pressurized air to blow out the chips every turn. Cut internal thread hand tap As a final step put the tap into a tap wrench ball tap. Begin cutting threads into the rod.

It also prevents the first and last thread from being pressed out of the hole. Take a scratch cut at the component without lubricant. RectangularHalf Die 8.

A bolt with flutes to provide cutting edges turned by a handle sets of taps. Thread chasing dies are used to restore old threads and cant be adjusted. Stop the spindle then check that the required thread pitch has been cut.

Chamfer the end of the metal. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. Cutting an external thread.

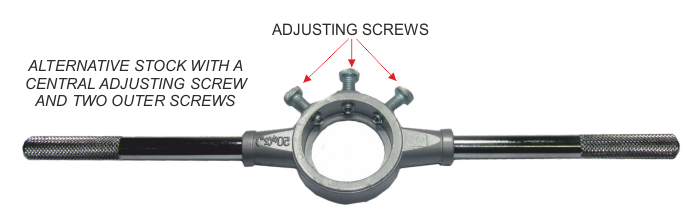

Both Imperial and Metric tap drill bit sizes are charted below. Do not open the half-nuts at the end of the cut. There is a small set screw on the side of the die itself.

The most commonly used dies in schools are split circular dies that are held in a die stock. Ensure the die is perpendicular to the rod and force is applied downward while rotating the die. Oil must be used to lubricate the.

The usual way of cutting screw threads in schools is by using a die held in a die stock. A modern workspace where engineering students can come together outside of the classroom to think experiment design build and exchange ideas. Weve had our current 45 pc SAE and.

Will cut 25 threadscm. Clamp work securely in bench vice level and square. Return the carriage to the beginning point.

Turn stock 1 full turn then back off 12 turn to break off chips. There is a small set screw on the side of the die itself. It all depends on the die being either a thread chasing die or not.

Using a die handle is a common method of external thread cutting on the lathe. A little cutting oil or grease is wiped onto the tap to help it cut and to give the screw thread a smooth finish. This will give you a better entry into the hole when cutting the thread.

Rotate the extractor counterclockwise for a broken bolt or screw with a right-handed thread clockwise for a left-handed thread and remove broken bolt or screw. External threads such as for bolts and studs are made by using a tool called a DIE which is applied to a specific diameter of rod for the size and pitch of the threads you want to cut. Taper tap sufficient for through hole Plug tap Bottoming tap ISO 12 and 3 before machining a hole has to be drilled t provide the necessary allowance for the threads.

EXTERNAL SCREW THREAD CUTTING STEPS 1. This 4-minute video will give you the essential info required to cut threads and keep yourself from getting into trouble. Make a trial scratch cut as if 60º thread cutting and using the cross slide withdraw the tool at the end of the cut.

Disengage the half nut on the verge of the cut stop the lathe and back out the tool by the usage of the cross feed. Thread chasing dies are used to restore old threads and cant be adjusted. If you need a tap and die set on the cheap get the Harbor Freight Set s.

Material size must be equal to the outside diameter of the thread. Turn stock in direction of desired thread. It all depends on the die being either a thread chasing die or not.

1 THREAD CUTTING MANUAL Tap and Die usually for manual cutting of threads tap. Die inverted in stock to give clearer view of thread as it is cut - Buggy task - Axles - Design Technology On The Web. Make clockwise turns to start the threads and anti- clockwise turns to break the chip 5.

Cutting an external thread - NB. Set up the lathe and the work as for cutting a 60º thread detailed above.

Successful External Threads With A Die Mechanical Elements

How To Cut An External Thread In 2 Steps Youtube

Cutting External Threads With A Stock And Die

Cutting External Threads With A Stock And Die

Cutting External Threads With A Stock And Die

Cutting External Threads On A Lathe Volkel

Cutting External Threads On A Lathe Volkel

No comments for "Describe How to Cut External Threads Using Hand Dies"

Post a Comment